It’s fascinating to think that bowling dates back nearly 5,000 years, with evidence of the sport found in ancient Egypt.

Over the years, different cultures have developed their own forms of the game.

Today, the materials and methods used to make bowling balls have evolved significantly.

So, what exactly are modern bowling balls made from, and how are they manufactured?

What Materials Are They Made Of?

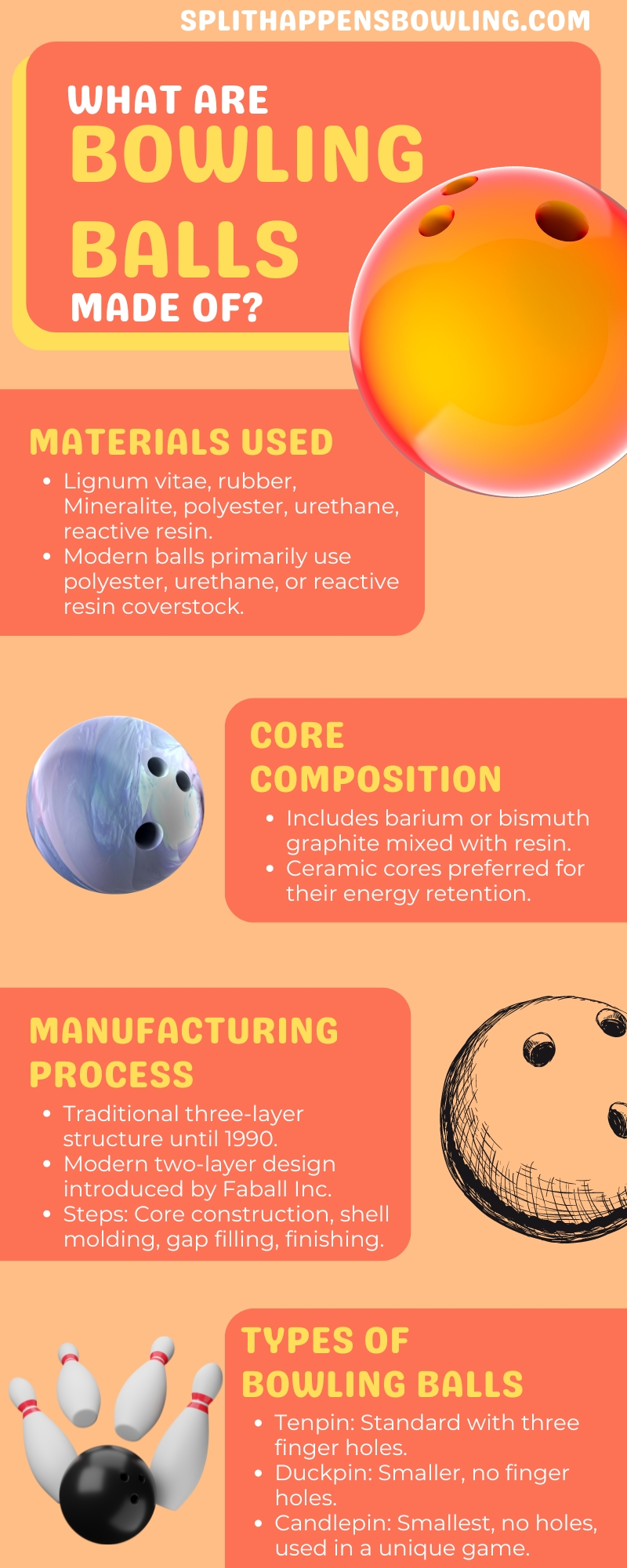

Bowling balls have been made from various materials over the centuries.

Originally crafted from a hardwood called Lignum vitae, the first rubber bowling ball, known as the Evertrue, was introduced in 1905.

In the 1910s, Brunswick Corporation launched a rubber ball made from Mineralite.

By 1970, the first polyester balls appeared, followed by urethane balls in the 1980s and reactive resin balls in the 1990s.

Modern bowling balls primarily use three types of coverstock: polyester, urethane, and reactive resin.

Polyester, the most affordable option, offers minimal hook potential because it doesn’t react much to lane oils.

Urethane, which is moderately priced, provides more hook than polyester and requires less maintenance than resin.

The most expensive, reactive resin, offers enhanced durability and hook potential.

The core of a bowling ball often includes materials like barium or bismuth graphite mixed with resin, forming either a ceramic or plastic-like core.

According to Track Inc., a bowling ball manufacturer, ceramic cores are more effective as they don’t absorb energy, unlike graphite or plastic cores. Iron oxide is sometimes added to enhance the ball’s center of gravity.

How Are They Made?

The manufacturing process for bowling balls has evolved significantly over time. Until 1990, bowling balls typically had a three-layer structure.

This involved filling a mold with a dense material for the outermost layer, then adding a less dense material inside, and finally sealing it with a 1-inch outer layer.

Starting in 1990, Faball Inc. introduced the modern two-layer design for bowling balls, simplifying the manufacturing process. Here’s how these are made:

- Construct the core: Initially, a core is shaped and filled with another material to create a spherical form.

- Make the shell: This core is then placed into a second mold for the coverstock. It’s fixed in place with a pin to ensure it remains centered. The coverstock material is then poured around the core to form the outer layer of the ball.

- Fill in the gaps: After the ball is removed from the coverstock mold, the hole left by the pin is visible. This hole is filled with a plastic dowel, and then the rest is filled with matching material to smooth out the surface.

- Finish: The final steps include shaving down any irregularities, resurfacing, sanding, and polishing the ball to ensure it meets quality standards and performs well in bowling alleys.

After the final steps of polishing the ball to ensure its optimal performance in bowling alleys, it’s essential for bowlers to regularly clean their bowling balls to maintain their condition and longevity.

Types of Bowling Balls

- Tenpin: These are the standard balls used in bowling alleys, featuring three holes for the thumb, middle, and ring fingers. They are designed to knock down ten pins in the game. When choosing your first bowling ball, consider starting with a tenpin ball for its versatility and familiarity.

- Duckpin: Smaller than tenpin balls, duckpin balls measure about 4.75 to 5.00 inches in diameter and do not have any finger holes. They are used to knock down pins that are 60% smaller than those used in tenpin bowling.

- Candlepin: The smallest type, candlepin balls have no holes and weigh around 2 lbs. They are used in a game where the pins are significantly smaller than in standard bowling, and only five pins are set up per frame.